Iowa Industrial Moderated Newsgroup For Surplus Equipment > Food Service

> Microwaves

> Needing Repair

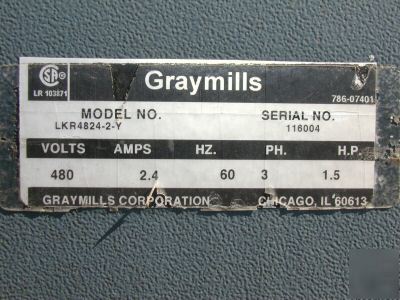

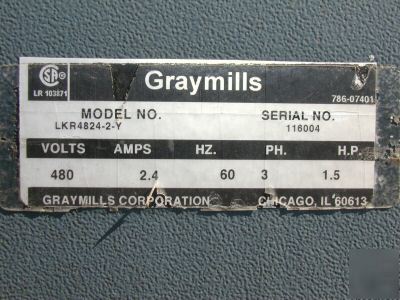

> Graymills liftkleen industrial parts cleaner

Graymills liftkleen industrial parts cleaner

Model # LKR4824-2-Y Serial # 116004

Volts 480, Amps 2.4, Hz. 60, Ph. 3, HP 1.5

The following is supplied from the manufacturer.

The Graymills Liftkleen is a heavy-duty multifunction,

commercial type parts cleaner designed

for both industrial and automotive applications. It

is available for use with either heated aqueous or

solvent cleaning solutions. Seven basic tank sizes

are offered ranging from 170 gallon capacity to

667 gallons in capacity (see Table 1 for

dimensional data). A pneumatic lift platform is

A number of optional features are available to

tailor the unit to a specific cleaning application.

• Superflo Pumping Unit with an output of up to

• Filtration system for the cleaning solution.

• Roller conveyor platform (instead of standard

grate), loading and unloading conveyors.

• Cleaning cycle and heater timers.

• Three 4.5 KW electric, immersion type

heaters and insulated tank depending on

The general arrangements of the Models LKR and

LKD Liftkleen assemblies, including optional

features, are shown in Figures 1 and 2. The

following paragraphs describe specific

The Liftkleen was designed to withstand the

rugged demands of heavy-duty industrial and

automotive parts cleaning. The tank is leaktested

after welding. The bottom of the tank

utilizes double wall construction and is

supported by four channels. Openings are

provided to facilitate moving the Liftkleen with

a fork-lift truck. A 1-1/2†NPT drain is located

in the bottom of the tank to which permanent

drain connections can be attached. An

overflow port is part of the tank assembly and

is intended for use with heated models only.

A water fill port is located in the rear of the

tank (see Figure 8) and consists of 3/4†NPT

pipe nipple. On optional heated models, the

tank sides and cover are insulated with 1â€

thick polystyrene foam (equal to two-plus

• PLATFORM AND LIFTER ASSEMBLY

The Platform and Lifter Assembly are

designed to handle loads specified for the

particular model of Liftkleen (see Table 2).

The platform consists of an angle iron frame

which supports an open steel grate. The lifter

assembly is made up of a channel weldment,

platform support weldment, four support

rollers with needle bearings and hardened

shafts, and a pneumatic cylinder. (Air

consumption data can be found in Table 3).

The rollers and bearings on all Model LKR

and LKD units are located outside the tank

and therefore never immersed in the cleaning

solution. This helps keep moving parts

lubricated. The standard open steel grate of

the platform assembly can be replaced with

the optional roller conveyor platform.

The Superflo Pumping Unit Assembly, an

units, is capable of providing 10,000 gallons

per hour of flow and provides exceptional

liquid agitation for quicker, more effective

parts cleaning. It is especially effective on

parts containing holes. The pump is a

centrifugal unit and is driven by an electric