Iowa Industrial Moderated Newsgroup For Surplus Equipment > Food Service

> Microwaves

> Used

> Sawmill, kiln operators manuals cd 1200 pgs. save$$$$

Sawmill, kiln operators manuals cd 1200 pgs. save$$$$

Why we are better then the rest????

Unlike everyone else, I offer All the manuals for one price and its available via download immediately after purchase. Don't Wait 3 weeks for your CD like some other sellers make you wait.

This is the most comprehensive manual you will find out there, if you are not satisfied then you have my money guarantee that I will give you a full refund.

Escalating Dimensional Lumber Prices!

Sawing your own lumber makes more sense than ever!

This downloadable manual helps you do-it-right the First Time!

Whether you're just starting out or you've cut thousands of board feet of lumber, you will benefit from the information contained in these manuals.

22 FULL LENGTH MANUALS and ARTICLES!

Here is what's included on this jam-packed cd.

Dry Kiln Operators Manual 269 pages.

1 Properties of wood related to drying 1

3 Dry kiln auxiliary equipment 75

4 Inspection and maintenance of dry kilns

5 Stacking and loading lumber for kiln drying 103

A Simplified Procedure For Developing Grade Lumber From Hardwood Logs.

15 Pages describing the best sawing techniques, to give you the best yield from your hardwood logs.

Air Drying Information Pack 21 Pages

i. Aim of the information pack 3

ii. The importance of drying timber....... 3

iii. Reasons for drying timber....... 3

2. Important concepts related to timber drying. 3

ii. Equilibrium moisture content...... 4

iii. Shrinkage and swelling..... 4

iv. Climate changes in the Chilterns 6

v. Equilibrium moisture contents for different end uses 7

4. Practical issues for air drying timber. 8

i. Preparing the site for air drying 8

iv. Constructing the stack......... 9

x. Other stacking procedures for air drying 11

xi. Health and safety issues...... 12

5. Monitoring the progress of the air drying process....... 12

ii. Assessing the progress of drying...... 13

iii. Determining moisture content.... 13

iv. Storage after air drying...... 13

6. Reducing degrade and distortion..... 14

ii. Degrade characteristics of selected timbers.... 15

iii. Sawing tips to help drying...... 16

v. The economics of air drying..... 16

10. Lists of useful contacts and references 21

Introduction ......................................................................... 1

1. Why Dry Lumber?.......................................................... 3

Drying Methods .............................................................. 3

Objectives ....................................................................... 4

Advantages and Limitations............................................ 6

2. Wood Properties and Moisture....................................... 7

Structure.......................................................................... 7

Moisture Content .......................................................... 10

Methods to Determine Moisture Content...................... 10

Moisture Movement...................................................... 12

Equilibrium Moisture Content ...................................... 14

Fiber Saturation Point ................................................... 14

Shrinkage ...................................................................... 14

Weight .......................................................................... 18

Color ............................................................................. 18

3. Air-Drying Process ....................................................... 21

Utilizing Air Movement................................................ 21

Factors That Influence Drying Rate.............................. 21

Drying Time and Final Moisture Content ..................... 23

Deterioration of Lumber ............................................... 25

4. Air-Drying Yard ........................................................... 27

Yard Layout and Orientation ........................................ 27

Yard Transportation Methods....................................... 29

Pile Foundations ........................................................... 29

Shed Drying.................................................................. 31

Yard Operation and Maintenance ................................. 32

5. Piling Methods For Air Drying..................................... 33

Sorting Lumber ............................................................. 33

Sorting Equipment ........................................................ 34

Stacking Lumber in Packages ....................................... 34

Stacking Random Length Lumber ................................ 38

Special Piling Methods ................................................. 38

Stickering Lumber ........................................................ 39

6. Air-Drying Defects—Causes and Remedies................. 43

Chemical Reaction........................................................ 43

Fungal Infection............................................................ 43

Insect Infestation........................................................... 44

Shrinkage ...................................................................... 44

Warp Reduction............................................................ 48

Stacking, Package Piling, and Pile Protection .............. 49

7. Protection of Air-Dried Lumber ................................... 51

Outdoors ....................................................................... 51

Indoors.......................................................................... 51

In Transit ...................................................................... 53

Appendix. Summarized Guide for Air-Drying Practices .. 55

Glossary............................................................................. 58

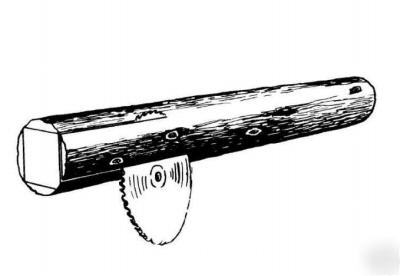

Circular Sawmills and Their Efficient Operation 93 pages

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

ACCURATE SAWING OF LUMBER . . . . . . . . . . . . . . . . . . . . . 1

EQUIPMENT SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Headsaw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SawArbor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Saw Collars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pulleys and V-Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Carriage and Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

EQUIPMENT SET UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mill Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Husk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

EQUIPMENT OPERATION AND MAINTENANCE . . . . . . . . . . . . . 47

Carriage and Saw Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Mill Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Headsaw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pulleys and V-Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Saw Arbor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Saw Collars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Carriage and Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Guide for Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Checklist for Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . 76

BIBLIOGRAPHY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

SPECIFIC GRAVITY VALUES . . . . . . . . . . . . . . . . . . . . . . . 81

STANDARD SAW GAGES . . . . . . . . . . . . . . . . . . . . . . . . . 85

Custom Portable Sawmill Enterprise

4 Page article. Good information for someone thinking of purchasing a portable sawmill.

Drying Hardwood Lumber 144 pages

Chapter 1 Overview......................................................... 1

Quality Requirements and Cost of Degrade .....................1

Basic Drying Concepts .....................................................1

Drying Methods................................................................3

Moisture Content..............................................................5

References ....................................................................... 6

Chapter 2 Drying Mechanisms of Wood........................ 7

Wood Characteristics That Affect Drying........................7

Environmental Factors....................................................12

Rate of Drying................................................................18

Stages of Drying.............................................................21

References .....................................................................24

Chapter 3 Stock Preparation and Stacking................. 25

Protection of Logs ..........................................................25

Sawing Procedures .........................................................25

Protection of Green Lumber...........................................26

Prevention of Surface Checks.........................................27

Prevention of End Checks ..............................................27

Color Enhancement Through Steaming..........................28

Other Lumber Pretreatments ..........................................28

Sorting............................................................................29

Stacking..........................................................................30

Additional Ways to Control Warp..................................33

References ......................................................................33

Chapter 4 Air Drying .................................................... 35

Advantages and Limitations ...........................................36

Utilization of Air Movement ..........................................36

Other Factors That Affect Drying Rate and Degrade .....37

Drying Time and Final Moisture Content.......................40

Air Drying and Shed Drying Operating Costs ................43

Quick Guide for Improving Air Drying..........................43

References ......................................................................44

Chapter 5 Drying Sheds .................................................45

Open Sheds.....................................................................45

Fan Sheds .......................................................................46

References ......................................................................47

Chapter 6 Accelerated Air Drying and Predrying...... 49

Accelerated Air Drying ..................................................49

Warehouse Predrying .....................................................50

References ......................................................................56

Chapter 7 Conventional Kiln Drying .......................... 57

Dry Kiln Designs............................................................57

Dehumidification Drying................................................58

Basic Kiln Operating Philosophy ...................................60

Kiln Samples ..................................................................60

Recording of Drying Date ..............................................71

Basic Hardwood Kiln Schedules ....................................72

Tropical Hardwoods.......................................................78

Kiln Start-Up Procedures ...............................................79

Equalizing and Conditioning..........................................86

Sterilization ....................................................................88

Drying Time ...................................................................88

Operational Considerations ............................................90

References ......................................................................91

Chapter 8 Advanced Kiln Drying Procedures............. 93

Modifications to General Hardwood Schedules .............93

Special Hardwood Schedules .........................................94

Adjustment of Moisture Content of Kiln-Dried Wood...95

Alternative Schedules for Some Species ........................96

Kiln Operational Techniques..........................................97

References ....................................................................102

Chapter 9 Drying Defects............................................ 103

Checking.......................................................................103

Shake............................................................................105

Collapse........................................................................106

Warp.............................................................................106

Discoloration................................................................107

Problems Caused by Incorrect Lumber

Moisture Content..........................................................109

Residual Tension set (Casehardening)..........................110

Machining and Gluing Problems ..................................110

Insect Damage ..............................................................111

Statistical Process Control............................................112

References ....................................................................114

Chapter 10 Special Drying Methods .......................... 115

Heated-Room Drying ...................................................115

Press Drying .................................................................115

High-Frequency and Microwave Heating.....................115

Solvent Seasoning ........................................................116

Lesser-Used Drying Methods.......................................116

Solar Drying .................................................................116

References ....................................................................118

Chapter 11 Storage of Dried Lumber ........................ 119

Air-Dried Lumber.........................................................119

Kiln-Dried Lumber.......................................................119

Storage Facilities ..........................................................119

References ....................................................................120

Chapter 12 Economics and Energy ............................. 121

Economics ....................................................................121

Energy Considerations..................................................122

References ....................................................................125

Appendix A—Lumber, Tree, and Botanical Names

of Commercial North American Hardwoods.............. 126

Appendix B—Portable Electric Moisture Meters...... 128

Glossary ......................................................................... 131

Electric Moisture Meters for Wood

19 Page USDA manual. Plenty of good information.

12 Page USDA report focusing on proper drying of oak lumber.

Considerations in Drying Hardwood Lumber

Report detailing drying theory for hardwood lumber.

Income Opportunities In Special Forest Products 203 pages

Excellent Source of ideas on other money making products in the wood lands around us!!

Introduction ...........................................................................................................................................7

Chapter 1. Aromatics...........................................................................................................................9

Chapter 2. Berries and Wild Fruit ......................................................................................................17

Chapter 3. Charcoal...........................................................................................................................25

Chapter 4. Chips, Shavings and Excelsior, Sawdust, Bark, and Pine Straw ......................................31

Chapter 5. Cones and Seeds ...............................................................................................................37

Chapter 6. Cooking Wood, Smoke Wood, and Flavorwood..............................................................45

Chapter 7. Decorative Wood..............................................................................................................49

Chapter 8. Forest Botanicals as Flavorings, Medicinals, and Pharmaceuticals .................................55

Chapter 9. Greenery, Transplants, and Floral Products .....................................................................73

Chapter 10. Honey.............................................................................................................................129

Chapter 11. Mushrooms .....................................................................................................................139

Chapter 12. Nuts................................................................................................................................155

Chapter 13. Recreation and Wildlife Recreational Enterprises..........................................................163

Chapter 14. Syrup..............................................................................................................................177

Chapter 15. Weaving and Dyeing Materials ......................................................................................189

Chapter 16. Specialty Wood Products................................................................................................197

EXCELLENT Resource for identifying the trees of the forest!! Very clear illustrations, combined with detailed descriptions of many species of trees.

Low Technology Kilns, and Drying Schedules for Hardwood in Small Scale Operations 8 pages

Good information targeted toward small and start-up lumber sawyers.

Method to Estimate Dry Kiln Schedules

Introduction................................................................1

Estimation of Kiln Schedules.........................................1

Background .............................................................1

Related Research...................................................1

Current Kiln Schedules ..........................................1

Method of Schedule Estimation...................................2

Estimation of Initial Conditions ..............................2

Estimation of Schedule Step Changes.......................4

Calculation of Kiln Schedules .................................5

Estimation of Tropical and Temperate Schedules ............5

Species Grouping Method.............................................6

Background .............................................................6

Estimation of Drying Time........................................7

Conclusions .............................................................10

Literature Cited.........................................................12

Appendix A—Specific Gravity Conversion....................14

Appendix B—Method to Estimate Drying Time.............14

Appendix C—Species Data for Kiln Drying...................14

21 Page article with excellent information of what happens when wood dries.

4 Page report covering low cost wood drying.

The Shrinking and Swelling of Wood

26 Pages covering why wood does what it does. Good information for gaining an understanding of wood movement when it's assembled into furniture.

Uses for Sawdust, Shavings, and Wood Chips 48 pages

What to do with waste products. Don't send it to the landfill and pay to dump it, sell it to increase your profits!

Using Portable Sawmills to Produce High Value Timber 141 pages

Foreword....................................................................................................................... iii

Acknowledgements.........................................................................................................iv

Table of contents .............................................................................................................v

List of Figures........................................................................................................... vii

List of Tables ..............................................................................................................xi

Executive Summary ..................................................................................................... xii

1 Introduction..............................................................................................................1

1.1 Farm forestry development ..................................................................................1

1.2 Resource issues ....................................................................................................3

1.3 Processing issues..................................................................................................4

1.4 Structure of the research project ..........................................................................6

2 Literature Review ....................................................................................................7

2.1 The supply and markets. ......................................................................................7

2.2 Wood Characteristics .........................................................................................13

2.3 Potential products from the trees .......................................................................16

2.4 Sawing Technology............................................................................................18

2.5 Portable milling..................................................................................................21

3 Sawing Equipment and Timber Species ..............................................................23

3.1 Portable Sawmills ..............................................................................................23

3.2 Equipment ..........................................................................................................33

3.3 Sawing procedures .............................................................................................36

3.4 Species selection criteria....................................................................................39

3.5 General characteristics of species used in trials.................................................42

4 Initial Sawing Trials ..............................................................................................49

4.1 Introduction........................................................................................................49

4.2 Aim ....................................................................................................................49

4.3 Materials and methods .......................................................................................50

4.4 Results................................................................................................................53

4.5 Discussion ..........................................................................................................58

4.6 Conclusion .........................................................................................................61

5 Circular Sawmill – Sawing depth, Tip width and Species .................................63

5.1 Introduction........................................................................................................63

5.2 Aim ....................................................................................................................63

5.3 Materials and methods .......................................................................................63

5.4 Results................................................................................................................65

5.5 Discussion ..........................................................................................................70

5.6 Conclusion .........................................................................................................75

6 Horizontal Bandsaw – blade configuration .........................................................76

6.1 Introduction........................................................................................................76

6.2 Aim ....................................................................................................................76

6.3 Materials and methods .......................................................................................76

6.4 Results................................................................................................................80

6.5 Discussion ..........................................................................................................85

6.6 Conclusions........................................................................................................88

Drying Hardwood for Quality 7 pages

Article describing methods to reduce profit loss when drying hardwood lumber.

Files are in Adobe Acrobat, and MS Word.

I'll also include 2 free files loaded with sawmill and lumbering suppliers, and manufacturers, and a publications list of other recommended reading.

****Don't Wait 3 weeks for your Manual like some other sellers make you wait. If you purchase this item from me you will be able to download it today, not wait days or weeks****

Satisfaction is guaranteed, you don't like it you can send it back and I will give a full refund. We stand behind our product. Item must be postmarked within 7 days of receiving.