Iowa Industrial Moderated Newsgroup For Surplus Equipment > Manufacturing Equipment

> Drills

> Used

> Promecam /amada 65 ton 10' up acting press brake cnc 2

Promecam /amada 65 ton 10' up acting press brake cnc 2

Note: I have the Amada name in the title and description, because Amada purchased the line and license to manufacture press brakes. If parts are ever needed, they can be purchased from Amada!

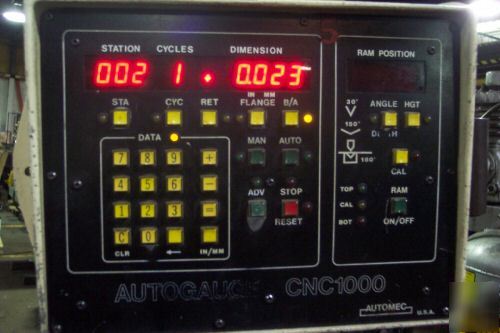

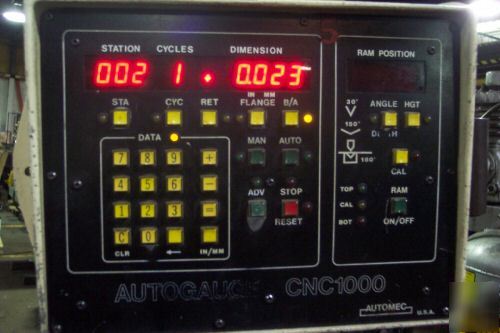

Here we have a nice up acting Promecam/Amada. Amada bought the patent to the promecam and has all the parts available. 10' Bed 104" Between Housings, 16" Gap Hydraulic, Two Axis Automec 1000 CNC Back Gauge, New in 1983 Model 65-30 Serial # 32-65-30-881 L-122"W-57.25"H-83" Weight Aprox 9,240#

* Save Time and Money With the Wilson Express Clamping System.

Express Clamping SystemAvailable for virtually any make and model of press brake, the Wilson Express Clamping System is uniquely designed to increase your productivity and reduce your operating costs.

Loading punches has never been easier. The Wilson Express Clamping system completely eliminates the need to slide punches in from the end of the machine. Simply place 16.34†(415mm) long punches or individual pieces of sectionalized punches under the clamps and push them upward. The spring-loaded clamps capture the punch via safety groove and hold it in place until the clamps are locked. To lock the clamps, simply push the removable lever upward.

Unload Punches Quickly and Easily.

Again, Wilson has eliminated the need to slide punches to the end of the machine. Simply pull down the locking lever to unlock the clamp. Or, to remove smaller punch sections, pushing inward on the tops of the clamps opens the clamps and allows the operator to pull individual sections straight down. Clamps that are not in use can easily be removed from the punch holders by hand.

No Special Tooling Required.

Wilson Express Clamping Systems can be used with any standard European (Promecam®) style press brake tooling with a safety groove. You can use the same high quality Wilson tooling you currently own, without having to repurchase the system for every tool you order.

Because the Wilson Express Clamping System is mechanical rather than hydraulic, maintenance costs are virtually eliminated. And with no hydraulics there’s no risk of power failures causing clamps to release unexpectedly.

A dual clamping feature is available on all Wilson Express Clamping Systems for an additional cost. This added feature allows you to load punches with the safety groove facing forward or to the rear of the machine. Both front and rear clamps are opened and closed simultaneously when the locking lever is actuated.