Iowa Industrial Moderated Newsgroup For Surplus Equipment > Manufacturing Equipment

> Vises

> No Warranty

> Build small foundry oil fired tilting furnaces

Build small foundry oil fired tilting furnaces

bounce, yer money order will get lost in the mail and yer dog won't come home.

click on our "Contact Us" icon above for the quickest response to your questions.

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

BUILD SMALL FOUNDRY OIL FIRED TILTING FURNACES

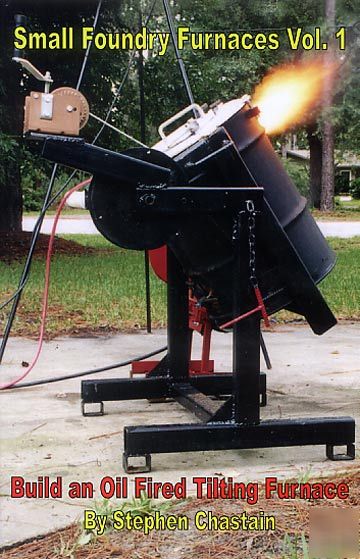

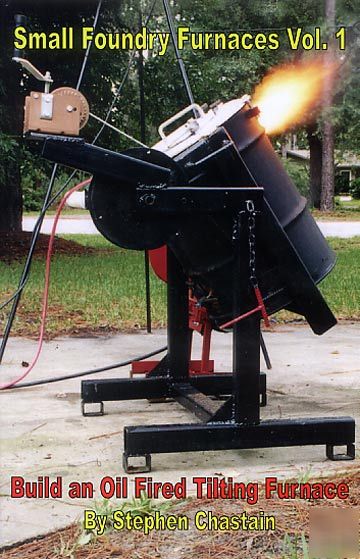

SMALL FOUNDRY FURNACES VOLUME 1: AN OIL-FIRED TILTING FURNACE

Dave Gingery's charcoal foundry is about all I need for the few castings that I need to pour. It's quick and easy to build, but it's not as convenient as it could be, and I'm limited to about a quart of molten aluminum. If you want to cast an aluminum boat, it won't do.

Here, Steve Chastain will show you how to build a furnace capable of melting fifty pounds of aluminum per melt which comes to about a hundred pounds per hour.

"The furnace is to be built from common materials such as sand, clay, pipe, rectangular tubing and an old 30-gallon drum. The furnace shown in this plan set may be built for $200 or less...".

And you fire it with propane or used motor oil.

"The furnace tilts around the spout and not the center of gravity so that the stream of molten aluminum remains in a fixed location and does not change with the furnace angle."

You get not only the details on building and firing this beaut, but Steve will give you the formulas and basic theory you need to make design changes to meet your own needs. You'll learn how to build a laminar flow burner nozzle, and how to proportion the design so that the furnace tilts safely and easily. And you'll be shown how to build the blower and a manometer. Then Steve will show how a furnace is built and used.

Tools? Well, you'll need a lathe to fabricate the venturi and a few small parts. You'll need a welder, and I think a power hacksaw or bandsaw sure would save the arm muscles. In other words, you ain't gonna build this on the kitchen table. But you ain't gonna need a giant machine shop either.

This book and the furnace it describes is worth having. Not only does Steve's book show you how to build a working furnace useful for pouring one-off large castings, or many small duplicate castings that can be sold, but it also shows you some of the basic furnace/combustion theory that goes into the design of a furnace.

5-1/2 X8-1/2 soft cover 192 pages

Visit my MarketplaceAdvisor Gallery! Power Tools for Power Sellers!

Phone: (***) 744-4449 M-F 9:00 to 4:00 Pacific Standard Time

This item has been seen by alt people!